RAWBRIGHT® PROCESSING SOLUTIONS

MULTI-LEVEL IMPINGEMENT FREEZER

RAWBRIGHT® International designed the Impingement Freezer for a small footprint. Instead of using a single belt like that in cryogenic freezers, this Impingement Freezer uses three conveyor straight belts that double production capacity per square metre of factory space.

The Multi-Level Impingement Freezer offers several advantages to frozen food processors, including higher load capacity, preserved product shape and flexibility to run different products on each level. The freezer’s unique and compact design also allows for efficient cleaning.

The Multi-Level Impingement freezer is suitable for applications up to 25 mm thick. It can be also used for crust freezing prior to slicing for a wide variety of larger products such as pork loin, larger fish and similar products.

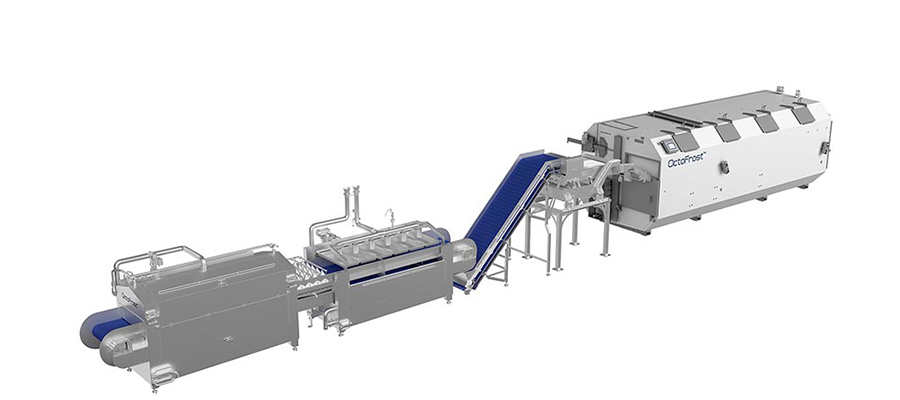

Optimized Connection Between IQF Line

Many times the food processors are not sure about which combination of processing machines that they need, how these can be optimized to work together, and who should be responsible for the whole line functionality when considering a number of different suppliers. The final freezing result and energy efficiency can be compromised if the equipment is not optimized or chosen right. Therefore, many processors prefer to have a single supplier for their complete processing line. This is where OctoFrost comes to help food processors with its innovative IQF technology that offers the advantage of having the most efficient equipment and a single supplier for the whole line.

IQF Food Processing Lines

Rawbright Tunnel Freezer

Because of its features, the IQF Freezer is known for creating unique aerodynamics. The bedplate configuration, overall freezer design and shape, and the high-performance fans with frequency converters contribute to a high-quality IQF result.

The IQF freezer is designed as an easily accessible monoblock uni, with rounded corners, sloping surfaces, and a Clean-in-Place (CIP) system. The bedplates can be exchanged with ease for efficient cleaning, which minimizes the risk of cross-contamination between different product batches.

Rawbright Processing Line Products

Nut Processing Technology

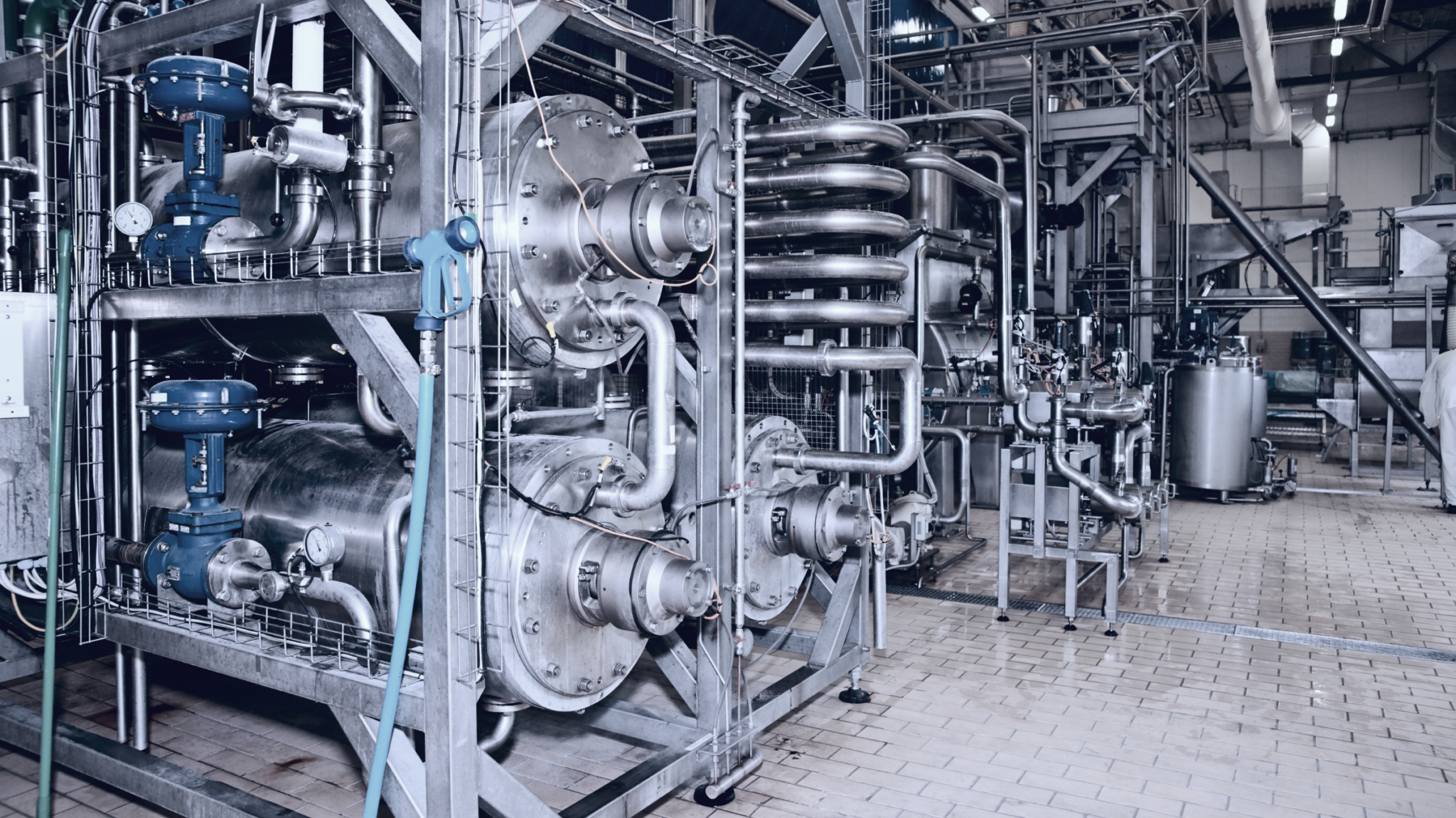

Peanuts and other types of nuts require extra care when fried. Unlike other snacks, these intake less oil and require better cleaning. The direct result is a longer frying oil turnover time and a higher chance of oil degradation. An advanced system is required to ensure the overall quality of oil remains optimal and you as a snack producer deliver a safe and tasty product.

Together with our clients and the continuous effort of the RAWBRIGHT® International team the peanut processing plant has been perfected and is in continuous development. Today we present snack manufacturers worldwide with the most advanced frying system for nut processing. An innovative fryer design combined with an efficient filtration system and a fully controlled process ensures the frying oil quality is maintained and the taste of the product is not compromised.

A turnkey delivered project, fully pre-tested and pre-wired in our workshop before delivery. The plant is mounted in our unique mainframe where all the electric cabling and pneumatic air supply pipes can be carefully stored for a clean and safe design. This concept further allows our customers to rapidly and efficiently start up their line on site

Application of Nut Processing

RAWBRIGHT® International can offer nut processing companies a turnkey plant to fry various types of nuts such as peanuts, cashews, hazelnuts, cashews and more. The same equipment can also be used to produce various types of products. The nuts are fried , cooled and flavoured or salted, depending on the producers needs. The solution includes all the necessary components from frying to flavouring.

RAWBRIGHT® International also offers a complete solution for coated peanuts and other round shaped products. These delicious snacks are usually made of the core product and a simple coating of starch and water which is added gradually by our innovative coating system.

Battered nuts are another delicious alternative to enjoy between meals or with a fresh beverage. These nuts are similar to the coated products but have a more irregular shape due to the liquid coating that was earlier applied. The texture is also more moist and soft. RAWBRIGHT® International battering unit combined with the rest of the plant will help you produce these delicious snacks in the most optimal way.

Egg Production with Modern Poultry Equipment

For decades, RAWBRIGHT® International have been designing and distributing equipment for modern egg production worldwide. Everything started when the Big Dutchman founders invented the world’s first automatic, professional chain feeder in 1938.

The feed chain’s material and design proved to be timeless: the invention is still used in many modern feeding systems today.

Our Line of Business in Poultry

Poultry Processing Solutions

Producing healthy poultry meat in a cost-effective way is a complex business. Important issues such as animal welfare, food safety, resource consumption and environmental footprint must be taken into consideration while running a profitable business. As your partner in poultry processing, we design complete poultry processing solutions that provide our customers with a sustainable competitive advantage. From live bird handling to final product dispatch, we deliver efficient, flexible and reliable equipment that will help you grow your poultry business. Good solutions begin with a real understanding of processing needs and we advise you through all stages of the investment process – from production analysis, through solution design, equipment implementation and training to after-sales service.

Grain Processing

Between harvesting and grain-processing lies a fascinating world of technology. RAWBRIGHT® International is at home in this world and has successfully expanded its technology applications, solutions, product portfolio and services to build and strengthen our overall value proposition to the benefit of our clients.