Combining application and technology

We enable companies in the food, grains, animal feed, and fertilizer industries to find ways to innovate and improve their application processes. Our strong focus and yearlong experience within processing solutions allow us to understand and help your business and create a process that lives up to and exceeds your expectations.

IQF (Individual Quick Frozen)

The IQF industry is key for RAWBRIGHT and innovative solutions have been developed over the years to cater to the needs of this industry, particularly in terms of sanitary design and wash-down execution.

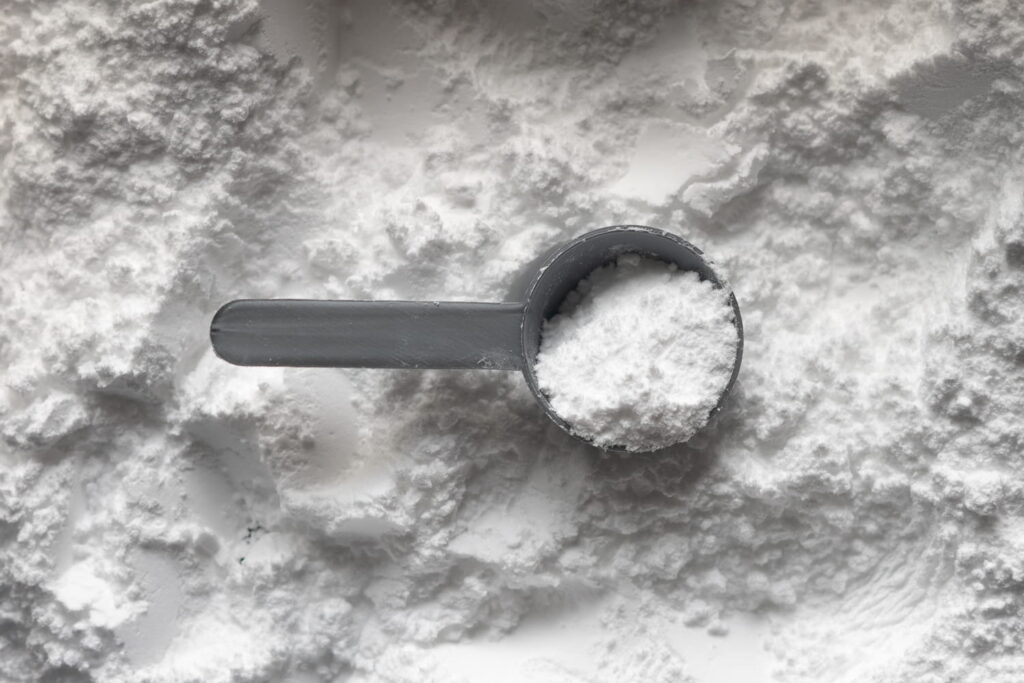

Dairy

Whether you need to design a new process for manufacturing dairy ingredients or optimise your current process, we have the technology and know-how to help you achieve your goals.

From process expertise and commercial advisory to all the equipment necessary for a complete milk or whey powder production process, we help minimise energy consumption without compromising product safety and quality.

From powder handling and mixing to liquid processing, spray drying and packaging, we can assist you with all the necessary technology and know-how to produce high-quality, nutritionally safe infant formula.

From extraction and concentration of raw materials to purification and final powder production, we have the knowledge and processing technologies to support the production of a high-quality lactoferrin product.

With the right technology and process design, lactose manufacturers can optimise yield and minimise waste in the lactose production process. We work with you to find the optimal solutions.

Food & Beverage

Animal-based proteins can be used as a functional ingredient in foods or for feed, for example in pet food. Producing the protein product involves either drying the blood as it is or separating it into plasma and haemoglobin.

We help food manufacturers produce flavours with state-of-the-art technology and services designed to optimise the spray- and freeze-drying process.

Our freeze-drying equipment and automated loading systems are highly suited to processing fruits and vegetables. Our specialists can help you design the optimal system for your market.

The manufacturing process of instant coffee continues to evolve and diversify. RAWBRIGHT offers equipment and services for manufacturing instant coffee based on your local requirements.

With our freeze-drying equipment and process know-how, you can establish an efficient, automated and flexible process for manufacturing instant tea.

For manufacturers of plant proteins, we offer everything from start-up to commissioning and equipment maintenance, helping you to ensure successful, sustainable operations.

We help yeast extract manufacturers achieve maximum product viability through a systematic, hygienic approach to process design.

Starch

An efficient, zero-waste process is essential to the success of your cassava/tapioca starch production line.

Discover how you can extract starch, protein, and fibre from faba beans in a zero-waste, commercially sustainable manufacturing process.

We can help you commercialise the extraction of starch, protein, and fibre from peas in a zero-waste, sustainable manufacturing process.

Potatoes offer great potential for commercially viable extraction of starch, proteins, fibres, and juice. Our process technology and expertise can help you make a business out of it.

With our state-of-the-art processing technology and industry-leading know-how, you can achieve efficient, sustainable and profitable rapeseed processing operations.

Create efficient, sustainable and profitable sago palm processing operations with our advanced food processing technology and know-how.

We provide the technology and know-how for some processes within different crops such as wheat, corn, rice, quinoa and other cereals. Our goal is to deliver the best output while minimising energy and water consumption.

With our unique technology concept, One-In-All-Out, you can manufacture high-quality food ingredients tailored for specific markets. The gentle bio-fractionation process enables you to maximise both utilization of plant raw materials and the valorization of side streams.

Nutraceutical

The manufacture of bovine colostrum requires maximum process stability and hygienic conditions. Built for Clean In Place, our hygienic processing equipment includes advanced robotics and is designed for ease of maintenance.

We provide state-of-the-art, tried-and-tested equipment and process knowledge to help you achieve a commercially viable production line for your starter cultures.

Design your probiotics production process for optimal temperature, humidity and air quality to ensure the best possible product quality.