RAWBRIGHT® International Fertilizer Industry

For the millions of farmers across worldwide, RAWBRIGHT® International is a name synonymous with prosperity and vision. Rawbright listens to its consumers, introducing novel lines of products addressing local soil and crop needs for farmers, Rawbright has been a friend and helping hand who cares for farmer education.

RAWBRIGHT® International guarantees the highest standards of plant nutrition products, which will promote yield and quality of crops. Our wide range of fertilizers are suitable for various crops such as green houses, open fields, landscapes, and can be used for all kinds of vegetables and fruit trees. We have solutions for all different types of soils and climate temperatures. These products are suitable for a wide range of applications.

RAWBRIGHT® International is a basic producer of many mineral fertilizers such as, Urea Phosphate (UP), Mono-Ammonium Phosphate (MAP) and Mono-Potassium Phosphate (MKP).

RAWBRIGHT® International fertilizer industries also produces a wide range of different NPK Water Soluble Fertilizers, Foliar NPK formulations, Suspensions fertilizers, liquid NPK formulations, Granular fertilizers, seaweed based products, soil correctors, different trace elements based products, bio-stimulants and adjuvants etc. Our raw materials are sourced out very carefully to insure the highest quality to achieve the satisfaction of our clients.

Rock Phosphate

RAWBRIGHT® International’s Rock Phosphate is defined as unprocessed ore and processed concentrates that contain some form of apatite, a group of calcium phosphate minerals that is the primary source for phosphorus in phosphate fertilizers, which are vital to agriculture.

Worldwide, more than 85 percent of the phosphate rock mined is used to manufacture phosphate fertilizers. The remaining 15 percent is used to make elemental phosphorus and animal feed supplements or is applied directly to soils. Elemental phosphorus is used to manufacture a wide range of chemical compounds which are used in the production of food additives, the manufacturing of detergents and toothpaste, the processing of meat products, cheeses, and drinks in the food industry, as well as in the production of batteries for electric vehicles.

Phosphate rock deposits can be sedimentary or igneous, but more than 80 percent of the world’s current production of phosphate rock is mined from sedimentary deposits formed by the deposition of phosphate-rich materials in marine environments. Large sedimentary deposits are located in China, the Middle East, northern Africa, and the United States.

Igneous deposits are associated with carbonatites and silica-deficient intrusions. These are mined in Brazil, Canada, Finland, Russia, South Africa, and Zimbabwe. Phosphate rock is mined mostly by surface methods using draglines and bucket wheel excavators for large deposits and power shovels or earthmovers for smaller deposits. Underground mines use the room-and-pillar method, similar to coal mining. In 2013, phosphate rock was produced almost entirely from surface mines, with only one active underground mine in the world.

We as the mine exploiter and seller of Rock Phosphate in the Mediterranean can supply your required Rock Phosphate directly from the mines. We can supply Rock Phosphate in the below range as per customers’ requirements.

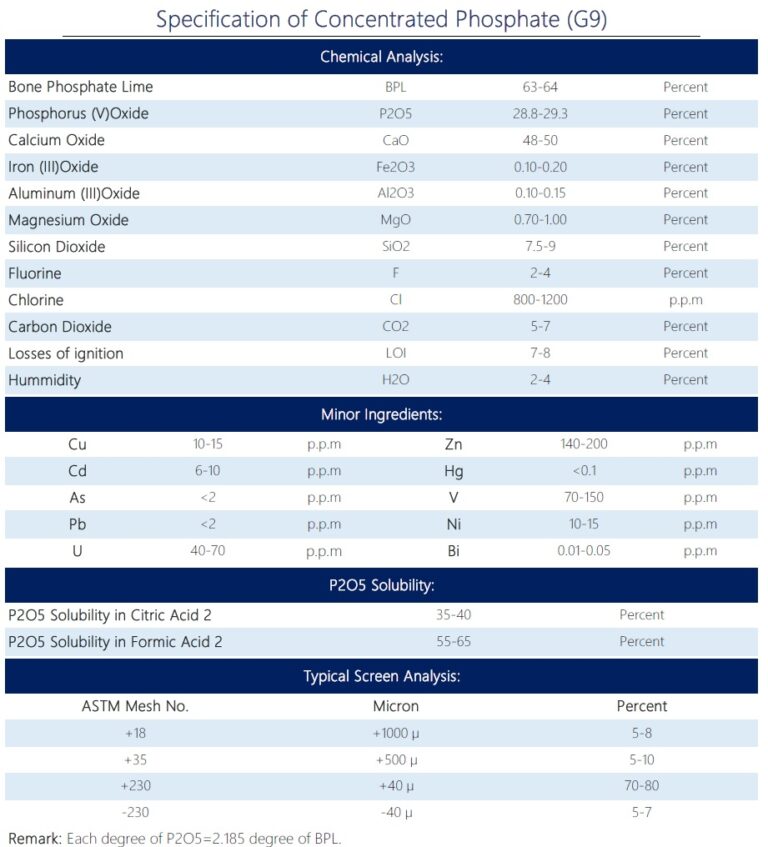

Rock Phosphate Types & Specfication of Concentrated Phosphate

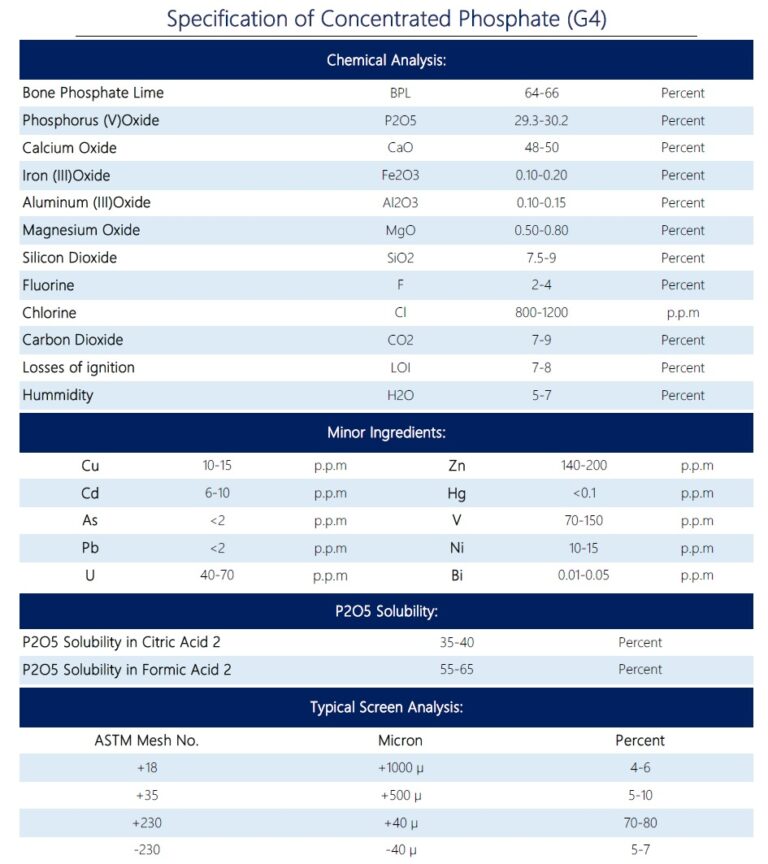

Currently, one of the best, is Rock Phosphate G4. The purity of P2O5 in this product is about 30% and its moisture range is between 5 to 7%.The percentage of iron in this product is between 0.1 to 0.2, which indicates that the percentage is low enough.

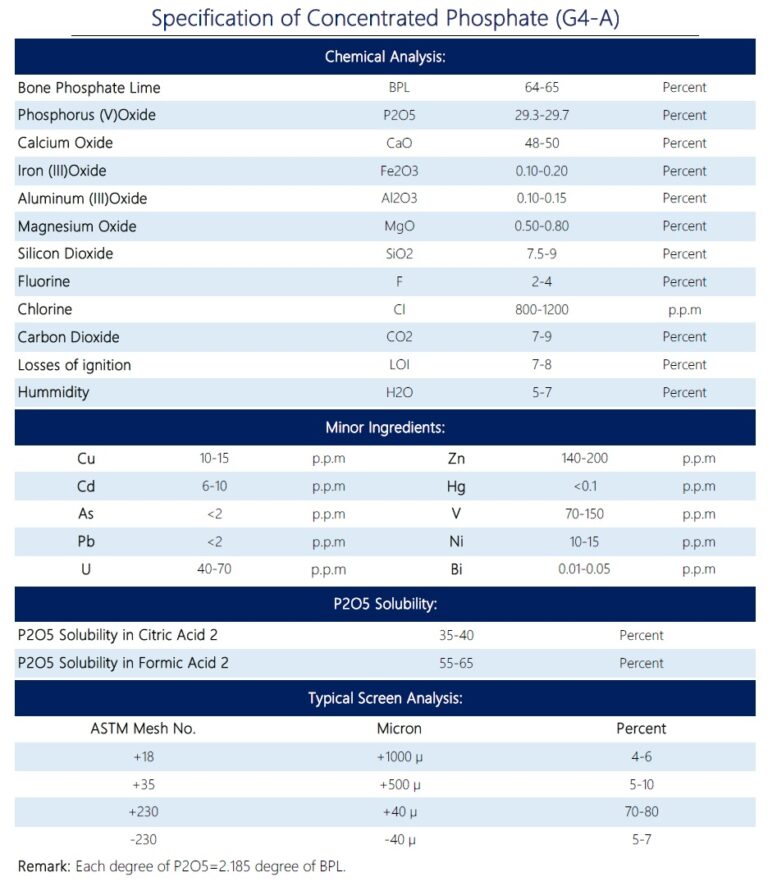

Currently, one of the best products is G4-A Rock Phosphate. The purity of P2O5 in this product is about 29% which is about 1% below the grade G4 and its moisture range is between 5 to 7%.The percentage of iron in this product is between 0.1 to 0.2, which indicates that the percentage is low enough.

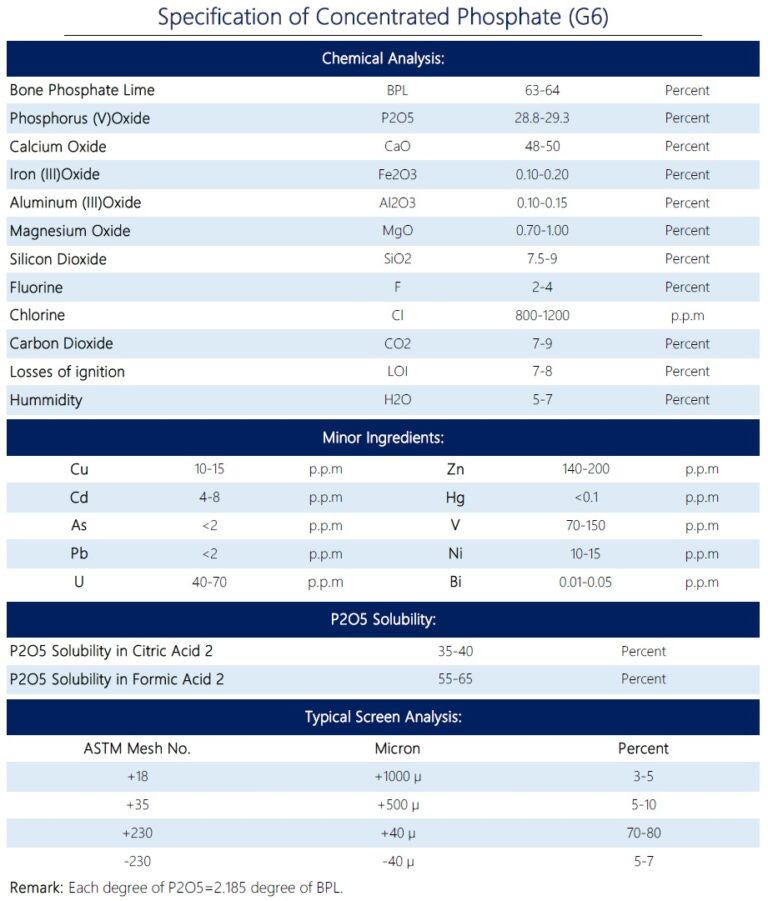

. The G6’s purity of P2O5 is about 29% which is about 1% below the grade G4, and about the purity of grade G4-A and its moisture range is between 5 to 7%.The percentage of iron in this product is between 0.1 to 0.2, which indicates that the percentage is low enough.

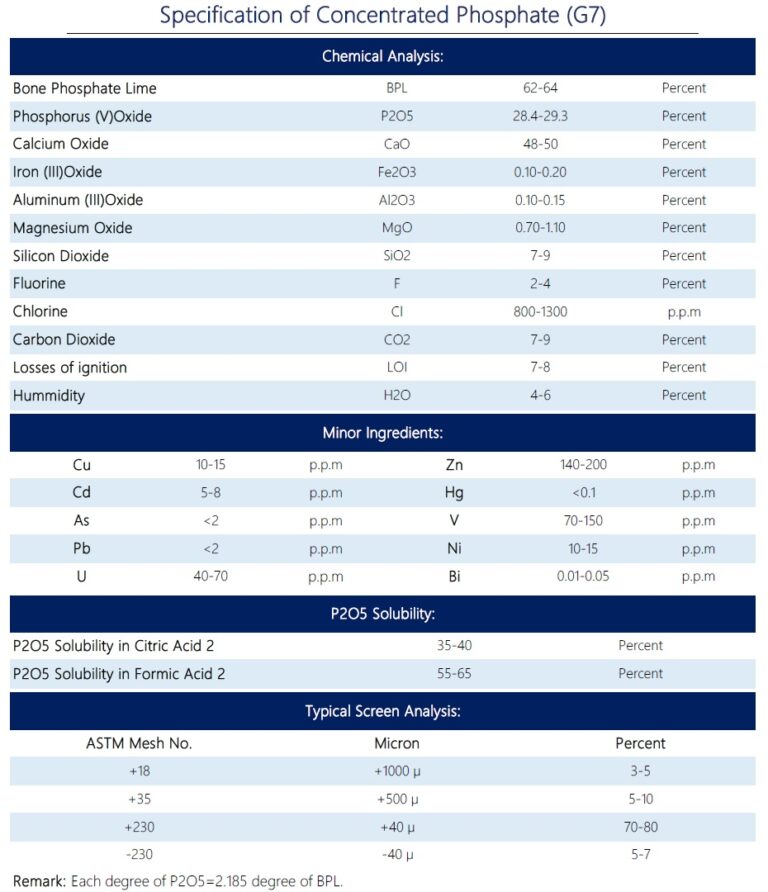

For factories that need a lower percentage of P2O5 which costs them lower too, we suggest the G7 grade of Rock Phosphate. The G7’s purity of P2O5 is about 28.5% which is about 1.5% below the grade G4, 1% below the grade G4-A and its moisture range is between 4 to 6%.The percentage of iron in this product is between 0.1 to 0.2, which indicates that the percentage is low enough.

For customers that need dry rock phosphate, we suggests the G9 product. The G9’s purity of P2O5 is about 29% which is about 1% below the grade G4, and about the purity of grade G4-A and its moisture range is between 2 to 4%.

The percentage of iron in this product is between 0.1 to 0.2, which indicates that the percentage is low enough.

Raw Material Products

RB Mono-Potassium Phosphate

Water soluble fertilizer contains a high rate of Phosphorous with Potassium. Fertilizer rich in micro-elements necessary to complete the plant nutrition. Fertilizer able to support plants nutrition needs especially to increase flowering & for high yield and roots development.

RB MONO AMMONIUM PHOSPHATE

A special fertilizer containing a very high percentage of phosphorus with nitrogen. It’s ideal to meet the nutritional needs of plants especially at the early stages to strengthen the roots development and to increase flowering. it comes under the brand name of MAPCO Singular.

RB POTASSIUM NITRATE

is a special fertilizer which contains a high percentage of Potassium & Nitrogen. it’s idea to meet the nutritional needs of plants especially during the vegetative growth & fruit development. It’s produced under the highest specifications.

Urea 46% Nitrogen

Urea, a white crystalline solid containing 46% nitrogen, is widely used in the agricultural industry as an animal feed additive and fertilizer Here we discuss it only as a nitrogen fertilizer.

Urea (46-0-0) usually has the lowest cost per pound of nitrogen compared to other single-element nitrogen fertilizers. However, urea undergoes unique chemical transformations when field applied and severe losses in efficiency may result if special management practices are not followed. The purpose of this fact sheet is to briefly describe urea transformations and to suggest how urea-N may be conserved with proper management in the field.

Fertilizer urea can be purchased as prills or as a granulated material. In the past, it was usually produced by dropping liquid urea from a “prilling tower” while drying the product. The prills formed a smaller and softer substance than other materials commonly used in fertilizer blends. Today, though, considerable urea is manufactured as granules. Granules are larger, harder, and more resistant to moisture. As a result, granulated urea has become a more suitable material for fertilizer blends.

Package

Urea is packed in polyethylene and propylene bags, in special containers for friable products, and also in other types of package.

Transportation

Urea can be shipped in bulk or packed with taking certain care measures; such as the possibility of getting the product into the environment and spilage of the product. Urea is transported by all transport facilities, in compliance with goods transportation regulations applied to this type of transport means.

Storage

Shelf life – 6 months from the date of production

Product Description

In common with most commercial nitrogen fertilizers, urea is manufactured from anhydrous ammonia (NH3). The high analysis of urea—46% N—is the main reason for the low cost of this form of nitrogen fertilizer. Freight costs and storage and handling are all lower than with lower analysis fertilizers such as ammonium nitrate (34-0-0) or ammonium sulfate (21-0-0).

Advantages of fertilizer urea

- – Can be applied to soil as a solid or solution or to certain crops as a foliar spray.

- – Urea usage involves little or no fire or explosion hazard.

- – Urea’s high analysis, 46% N, helps reduce handling, storage and transportation costs over other dry N forms.

- – Urea manufacture releases few pollutants to the environment.

- – Urea, when properly applied, results in crop yield increases equal to other forms of nitrogen.

- – Incorporate urea for best use

Nitrogen from urea can be lost to the atmosphere if fertilizer urea remains on the soil surface for extended periods of time during warm weather. The key to the most efficient use of urea is to incorporate it into the soil during a tillage operation. It may also be blended into the soil with irrigation water. A rainfall of as little as 0.25 inches is sufficient to blend urea into the soil to a depth at which ammonia losses will not occur.

If properly applied, urea and fertilizers containing urea are excellent sources of nitrogen for crop production. After application to the soil, urea undergoes chemical changes and ammonium (NH4 +) ions form. Soil moisture determines how rapidly this conversion takes place.

When a urea particle dissolves, the area around it becomes a zone of high pH and ammonia concentration. This zone can be quite toxic for a few hours. Seed and seedling roots within this zone can be killed by the free ammonia that has formed. Fortunately, this toxic zone becomes neutralized in most soils as the ammonia converts to ammonium. Usually it’s just a few days before plants can effectively use the nitrogen. Although urea imparts an alkaline reaction when first applied to the soil, the net effect is to produce an acid reaction.

Urea or materials containing urea should, in general, be broadcast and immediately incorporated into the soil. Urea-based fertilizer applied in a band should be separated from the seed by at least two inches of soil. Under no circumstances should urea or urea-based fertilizer be seed-placed with corn.